Product description:

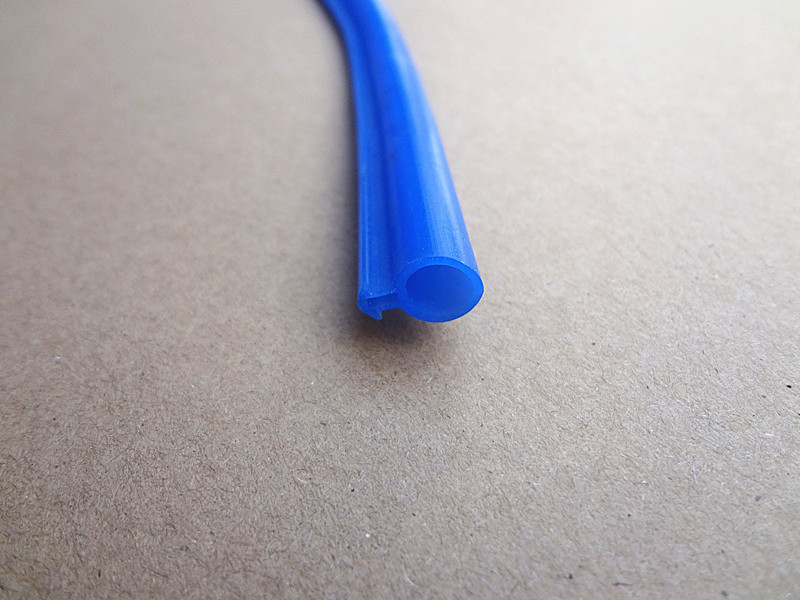

(1) Silicone rubber extrusion parts.

(2) EPDM&PVC rubber extrusion parts.

(3) Electrical apparatus fire resistance rubber parts.

(4) High and Low temperature resistant rubber parts.

(5) Electric conduct rubber parts.

(6) EPDM rubber foam/sponge parts.

(7) NBR dense parts.

(8) Silicone,EPDM & PVC molded parts.

(9) Other special TPV,TPO,TPR,TPU,PP,ABS,CPVC,PVC/NBR rubber extrusion parts.

Product Usage:

Vehicle ----------railway,subway,pathway,train,bus,truck,car,etc

Marine -----------boat,ship,sailing boat,etc

Construction -----building door window,guard,inflaming retarding,etc

Industry ----------various machines

Quality Control:

1.Best quality RAW rubber materials.

2.Advanced equipment and good workmanship.

3.Customer's design and specifications are accepted.

4.Rubber strips are made in various materials and be made in different sizes and color.

Other details:

Raw Material | EPDM,Silicone,NBR,CR,PVC,TPE,TPV,etc |

Color | Black,gray,white,blue,green,brown,transparent etc. |

Craft | Extrusion,molded,injection |

Temperature Range | EPDM - 40°C - 260°C Silicone - 60°C - 300°C PVC -30°C - 100°C TPE/TPV - 40°C - 280°C |

Hardness | 20~90 Shore A |

Feature | High and low temperature resistant, aging,old,weather,fire resistant,dust,water,corrosion,wearing,abrasion proof,inflaming retarding |

Lead Time | Samples lead time: 3-7 days Products lead time: 7-15 days Our products begin and end with strict adherence to our clients' budgeting and scheduling time |

Packaging | Plastic bags inside,carton boxes outside or customized |

Service | We can produce according to customers' drawings or samples |

窗体底端